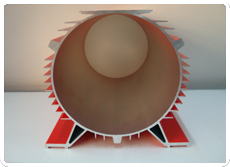

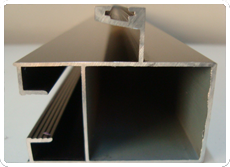

» Extrusion

We offer aluminum alloys such as 6060 / 6061 / 6063 (Al + Mg + Si). Our customers can count on quality aluminum "Premium"guaranteeing an improvement in the products.

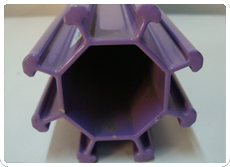

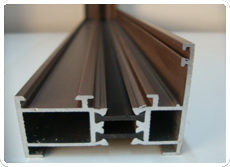

» Anodized

We work with upright plants from 5 to 50 microns.

Anodizing Types: |

Anodizing Colors: |

| » Acid Medium | » Natural |

| » Polishing | » Champagne |

| » Chemical | » Light Bronce |

| » Oxalic | » Medium Bronce |

| » Acid | » Dark Bronze |

| » Light Bronze Color to Black | » Black |

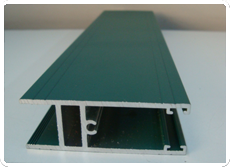

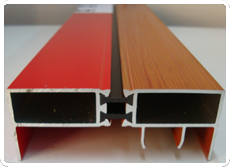

» Painting

We have both production plants vertical and horizontal, painting electrostatic polyester powder. The aluminum is treated prior to painting with chromate or anodized and then applies a heat treatment, then finish with the paint color you want.

The paint layers range from 50 to 100 microns depending on customer requirements and on the aggressiveness of the environment in which they intend to apply.

» 4 Types of Powder that we use

1. Polyester

2. Base Coat: Polyurethane Wood Effect

3. Super-Resistant Polyester

4. New Technology That is Highly Resistant

» 3 Types of Finishes

Categoría 1: Mate

Categoría 2: Semi Gloss

Categoría 3: Glossy and Very Glossy

» Colors

Generally we use all the RAL colors and metallic colors and woodgrain finishes in color.

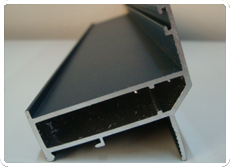

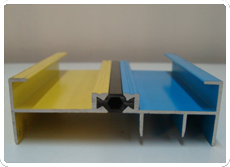

» Thermal Bridge

We use polyamides of 16mm to 24 mm for assembly between profiles.

This system saves energy of up to 25% compared to conventional systems without thermal break. The system also allows you to combine different colors and finishes between the exterior and interior.

» Packaging

We use for the packaging a paper between the aluminium profiles and / or a protective film on the surface for its protection.